Custom boxes play a key role in attracting and retaining customers to your brand. Oftentimes, their experience with your company begins with the box your products arrive in. Therefore, it’s important to know the best materials, styles, dimensions, and other specifications that will work for your products.

We’ll explain the basics of what you need to know about these packaging solutions, including how to order custom boxes from Imperial Paper—an industry leader in the custom packaging industry.

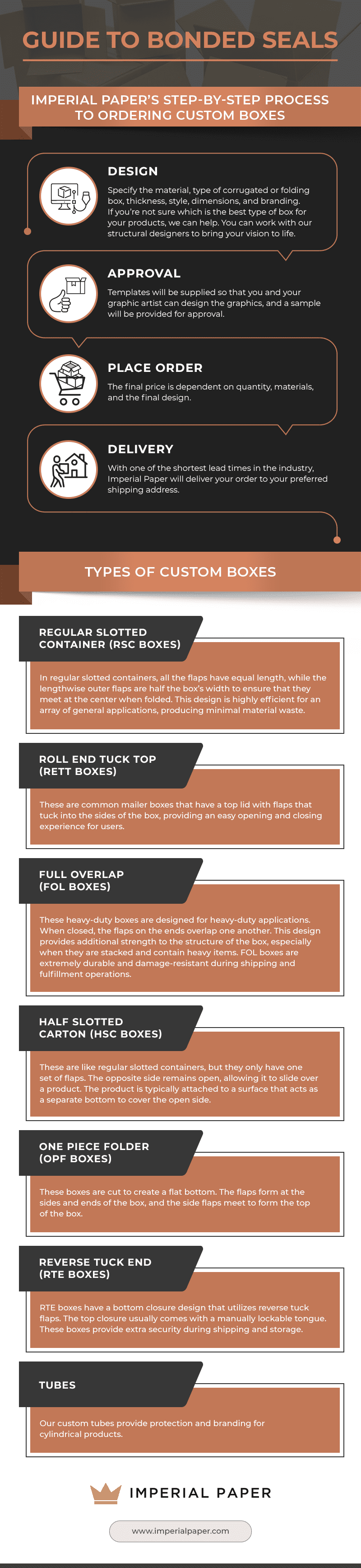

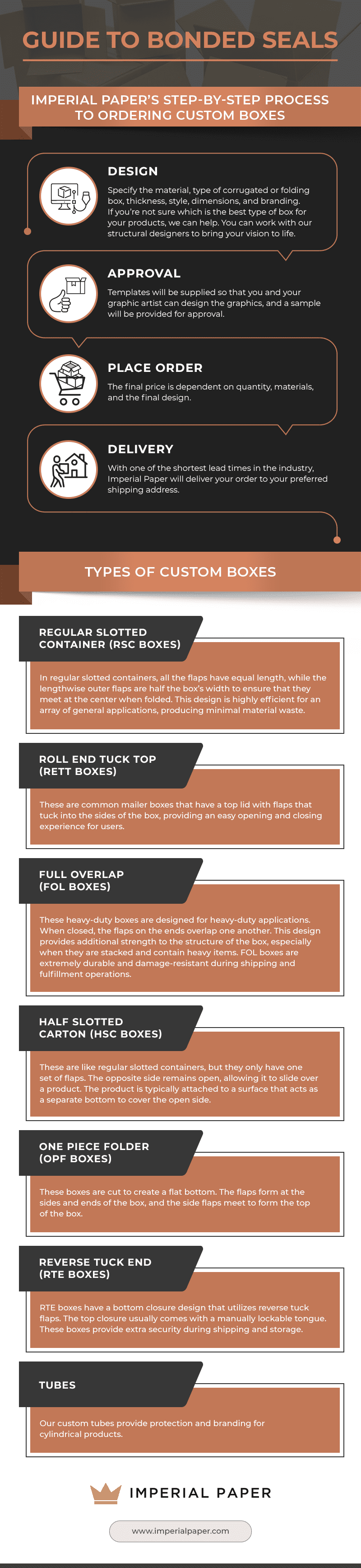

Imperial Paper helps organizations to create innovative and effective packaging solutions. The process of ordering custom boxes for your products follows these four simple steps:

Imperial Paper’s Step-By-Step Process to Ordering Custom Boxes

Imperial Paper’s Step-By-Step Process to Ordering Custom Boxes

Imperial Paper helps organizations to create innovative and effective packaging solutions. The process of ordering custom boxes for your products follows these four simple steps:

- Design. Specify the material, type of corrugated or folding box, thickness, style, dimensions, and branding. If you’re not sure which is the best type of box for your products, we can help. You can work with our structural designers to bring your vision to life.

- Approval. Templates will be supplied so that you and your graphic artist can design the graphics, and a sample will be provided for approval.

- Place order. The final price is dependent on quantity, materials, and the final design.

- Delivery. With one of the shortest lead times in the industry, Imperial Paper will deliver your order to your preferred shipping address.

×

![]()

Click to Enlarge

Types of Custom Boxes

Today, more than 90% of goods are shipped in corrugated boxes. This broad category of boxes encompasses a variety of stock and custom configurations. Imperial Paper offers seven main types of custom packaging boxes:- Regular Slotted Container (RSC Boxes): In regular slotted containers, all the flaps have equal length, while the lengthwise outer flaps are half the box’s width to ensure that they meet at the center when folded. This design is highly efficient for an array of general applications, producing minimal material waste.

- Roll End Tuck Top (RETT Boxes): These are common mailer boxes that have a top lid with flaps that tuck into the sides of the box, providing an easy opening and closing experience for users.

- Full Overlap (FOL Boxes): These heavy-duty boxes are designed for heavy-duty applications. When closed, the flaps on the ends overlap one another. This design provides additional strength to the structure of the box, especially when they are stacked and contain heavy items. FOL boxes are extremely durable and damage-resistant during shipping and fulfillment operations.

- Half Slotted Carton (HSC Boxes): These are like regular slotted containers, but they only have one set of flaps. The opposite side remains open, allowing it to slide over a product. The product is typically attached to a surface that acts as a separate bottom to cover the open side.

- One Piece Folder (OPF Boxes): These boxes are cut to create a flat bottom. The flaps form at the sides and ends of the box, and the side flaps meet to form the top of the box.

- Reverse Tuck End (RTE Boxes): RTE boxes have a bottom closure design that utilizes reverse tuck flaps. The top closure usually comes with a manually lockable tongue. These boxes provide extra security during shipping and storage.

- Tubes: Our custom tubes provide protection and branding for cylindrical products.