Click to Enlarge

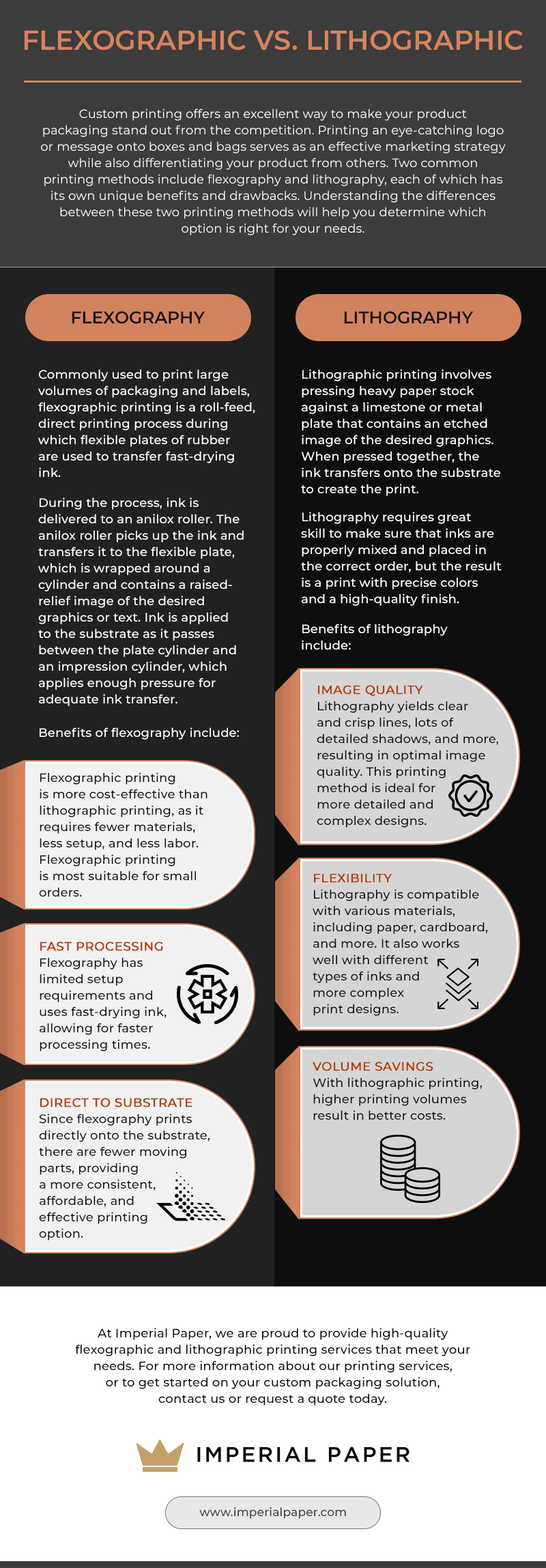

Custom printing offers an excellent way to make your product packaging stand out from the competition. Printing an eye-catching logo or message onto boxes and bags serves as an effective marketing strategy while also differentiating your product from others. Two common printing methods include flexography and lithography, each of which has its own unique benefits and drawbacks. Understanding the differences between these two printing methods will help you determine which option is right for your needs.

Since 1963, Imperial Paper has been providing high-quality packaging products and services, including flexographic and lithographic printing. Our highly trained team of printing experts will work with you to determine the best method for your project and create a custom printing solution designed to improve your company’s bottom line.

What is Flexography?

Commonly used to print large volumes of packaging and labels, flexographic printing is a roll-feed, direct printing process during which flexible plates of rubber are used to transfer fast-drying ink.

During the process, ink is delivered to an anilox roller. The anilox roller picks up the ink and transfers it to the flexible plate, which is wrapped around a cylinder and contains a raised-relief image of the desired graphics or text. Ink is applied to the substrate as it passes between the plate cylinder and an impression cylinder, which applies enough pressure for adequate ink transfer.

Benefits of flexography include:

- Flexographic printing is more cost-effective than lithographic printing, as it requires fewer materials, less setup, and less labor. Flexographic printing is most suitable for small orders.

- Fast processing. Flexography has limited setup requirements and uses fast-drying ink, allowing for faster processing times.

- Direct to substrate. Since flexography prints directly onto the substrate, there are fewer moving parts, providing a more consistent, affordable, and effective printing option.

What is Lithography?

Lithographic printing involves pressing heavy paper stock against a limestone or metal plate that contains an etched image of the desired graphics. When pressed together, the ink transfers onto the substrate to create the print.

Lithography requires great skill to make sure that inks are properly mixed and placed in the correct order, but the result is a print with precise colors and a high-quality finish.

Benefits of lithography include:

- Image quality. Lithography yields clear and crisp lines, lots of detailed shadows, and more, resulting in optimal image quality. This printing method is ideal for more detailed and complex designs.

- Flexibility. Lithography is compatible with various materials, including paper, cardboard, and more. It also works well with different types of inks and more complex print designs.

- Volume savings. With lithographic printing, higher printing volumes result in better costs.

Although digital printing methods typically allow for quicker setup and lower costs, lithographic printing is the superior option when working with heavier weights of paper and offers a more cost-effective method for printing large quantities.

Flexographic and Lithographic Printing from Imperial Paper

Flexographic and lithographic printing methods offer many advantages, and either option provides an excellent way to incorporate custom graphics onto product packaging. When choosing a printing method, it is important to consider factors such as substrate and printing volume to ensure you select the best and most cost-effective option for your project.

At Imperial Paper, we are proud to provide high-quality flexographic and lithographic printing services that meet your needs. For more information about our printing services, or to get started on your custom packaging solution, contact us or request a quote today.